Iwwersiicht

Kesselstahlblech, och Drockbehälterstahlblech genannt, enthält Kuelestol a Legierungsstol fir héich-, mëttler- an niddreg Temperaturen. Déi wichtegst Stahlqualitéiten an de Kesselstahlblech, déi mir liwweren, goufen vum däitschen TÜV an dem brittesche Lloyd's Register guttgeheescht. Eis MS-Kesselstahlblech gëtt haaptsächlech an Ueleg- a Gasfirmen, an der chemescher Industrie a Kraaftwierker fir d'Produktioun vu Reakteren, Wärmetauscher, Separatoren, sphäresche Panzer, Ueleggaspanzer, Drockhüllen fir Kärreaktoren, Héichdrockwaasserleitungen, Turbinenhüllen an aner Ausrüstung benotzt.

Technesch Ufuerderunge fir Kesselstahlblech

● P...GH- a P...N-Qualitéiten, déi ënner normaliséierter (N) Hëtztbehandlung duerchgefouert goufen.

● P...Q-Qualitéiten, déi ënner Hëtztbehandlung ënner Gehärtung an Temperéierung (QT) ofgeschloss goufen.

● Legierungsstol (S)A387, (S)A302, S(A)203, S(A)533 Qualitéiten, déi ënner normaliséierter an temperéierter (N+T) Hëtztbehandlung gemaach goufen.

● Ultraschalltest no ASTM A435/A435M, A578/A578M Level A/B/C, EN 10160 S0E0-S3E3, GB/T2970 Level I/II/III, JB4730 Level I/II/III.

Zousätzlech Servicer vum Jindalai Ssteel

● Héichspannungstest.

● Impakttest bei niddreger Temperatur.

● Simuléiert Hëtzebehandlung nom Schweessen (PWHT).

● Ënner der Norm NACE MR-0175 (HIC+SSCC) falen.

● Ausgestallten Original Mill Testzertifikat no EN 10204 FORMAT 3.1/3.2.

● Schossstrahlen a Lackéieren, Schneiden a Schweessen no den Ufuerderunge vum Endbenotzer.

All Stolqualitéiten aus Kesselstahlblech

| STANDARD | STOLKLASS |

| EN10028 EN10120 | P235GH, P265GH, P295GH, P355GH, 16Mo3 P275N, P275NH, P275NL1, P275NL2, P355N, P355NH, P355NL1, P355NL2, P460N, P460NH, P460NL1, P460NL2 P355Q, P355QH, P355QL1, P355QL2, P460Q, P460QH, P460QL1, P460QL2, P500Q, P500QH, P500QL1, P500QL2, P690Q, P690QH, P690QL1, P690QL2 P355M, P355ML1, P355ML2, P420M, P420ML1, P420ML2, P460M, P460ML1, P460ML2 P245NB, P265NB, P310NB, P355NB |

| DIN 17155 | HI,HII,17Mn4,19Mn6,15Mo3,13CrMo44,10CrMo910 |

| ASME ASTM | A203/A203M SA203/SA203M A203 Klass E, A203 Klass F, A203 Klass D, A203 Klass B, A203 Klass A SA203 Klass E, SA203 Klass F, SA203 Klass D, SA203 Klass B, SA203 Klass A A204/A204M SA204/SA204M A204 Klass A, A204 Klass B, A204 Klass C SA204 Klass A, SA204 Klass B, SA204 Klass C A285/A285M A285 Klass A, A285 Klass B, A285 Klass C SA285/SA285M SA285 Klass A, SA285 Klass B, SA285 Klass C A299/A299M A299 Klass A, A299 Klass B SA299/SA299M SA299 Klass A, SA299 Klass B A302/A302M SA302/SA302M A302 Klass A, A302 Klass B, A302 Klass C, A302 Klass D SA302 Klass A, SA302 Klass B, SA302 Klass C, SA302 Klass D A387/A387M SA387/SA387M A387Gr11CL1, A387Gr11CL2, A387Gr12CL1, A387Gr12CL2,A387Gr22CL1,A387Gr22CL2 SA387Gr11CL1, SA387Gr11CL2, SA387Gr12CL1, SA387Gr12CL2,SA387Gr22CL1,SA387Gr22CL2 A455/A455M A455, SA455/SA455M SA455 A515/A515M SA515/SA515M A515 Grad 60, A515 Grad 65, A515 Grad 70 SA515 Grad 60, SA515 Grad 65, SA515 Grad 70 A516/A516M SA516/SA516M A516 Klass 55, A516 Klass 60, A516 Klass 65, A516 Klass 70 SA516 Grad 55, SA516 Grad 60, SA516 Grad 65, SA516 Grad 70 A533/A533M SA533/SA533M A533GrA CL1/CL2/CL3, A533GrB CL1/CL2/CL3, A533GrC CL1/CL2/CL3, A533GrD CL1/CL2/CL3 SA533GrA CL1/CL2/CL3, SA533GrB CL1/CL2/CL3, SA533GrC CL1/CL2/CL3, SA533GrD CL1/CL2/CL3 A537/A537M A537CL1,A537CL2,A537CL3 SA537/SA537M SA537CL1,A537CL2,A537CL3 |

| JIS G3103JIS G3115 JIS G3116 | SB410, SB450, SB480, SB450M, SB480M SPV235, SPV315, SPV355, SPV410, SPV450, SPV490 SG255, SG295, SG325, SG365, SG255+CR, SG295+CR, SG325+CR, SG365+CR |

| GB713 GB3531 GB6653 | Q245R(20R), Q345R(16MnR), Q370R, 18MnMoNbR, 13MnNiMoR, 15CrMoR, 14Cr1MoR, 12Cr2Mo1R, 12Cr1MoVR, 16MnDR, 15MnNiDR, 09MnNiDR HP235, HP265, HP295, HP325, HP345, HP235+CR, HP265+CR, HP295+CR, HP325+CR, HP345+CR |

Detailzeechnung

-

SA516 GR 70 Drockbehälter Stolplacken

-

Kessel Stolplack

-

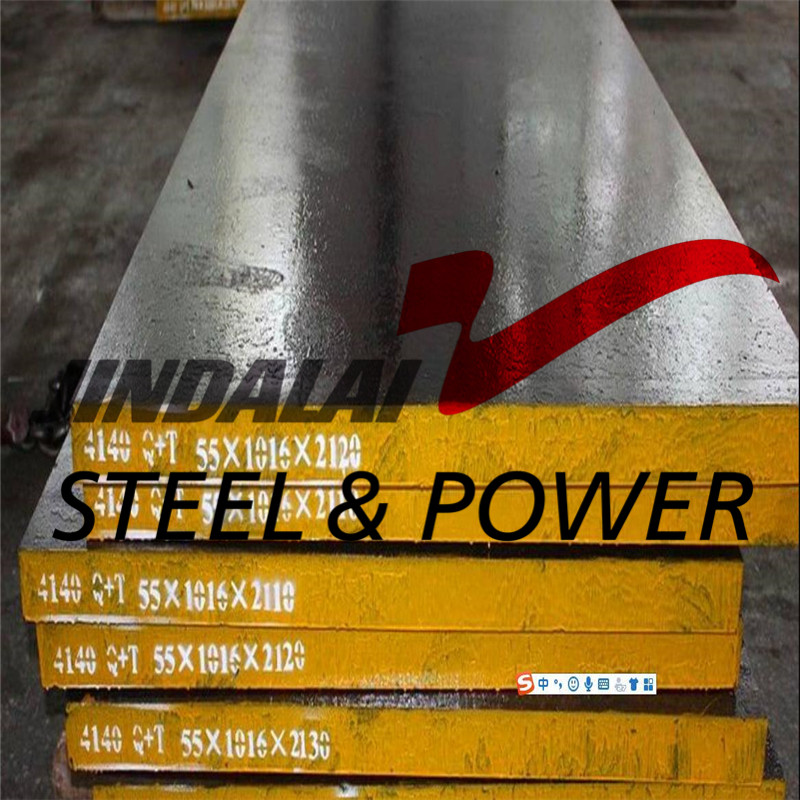

4140 Legierungsstahlblech

-

Eng 516 Grad 60 Gefässstahlplack

-

A36 Warmgewalzt Stolplackenfabréck

-

Abrasiounsbeständeg (AR) Stolblech

-

Marine Grad CCS Grad A Stolplack

-

Pipeline Stolplack

-

Marinequalitéitsstahlblech

-

S235JR Kuelestolplacken/MS-Plack

-

SA387 Stolblech

-

Schëffsbau Stolblech

-

ST37 Stolplack / Kuelestolplack

-

S355J2W Corten Placken Verwitterungsbeständeg Stolplacken

-

S355G2 Offshore Stolblech